How Bricks Are Replacing Natural Gas in Germany

I must confess, I have a soft spot for technology that feels strangely “retro” yet is undeniably futuristic. We usually talk about quantum computing or AI algorithms here, but today, I want to talk about something much simpler: Bricks.

Yes, you read that right. While the world is obsessed with lithium-ion and solid-state batteries, the heavy industry in Germany is starting a revolution with… hot bricks.

I was reading about the latest partnership between Covestro and Rondo Energy, and honestly, it put a smile on my face. It’s a perfect example of how the solution to our most complex energy problems (like getting off natural gas) might just be hiding in plain sight.

Let’s dive into what’s happening in Brunsbüttel and why I think this is a game-changer for the industrial sector.

The “Heat Battery” Concept: Simple, Yet Brilliant

If you look at the energy transition, the hardest part isn’t electrifying cars; it’s decarbonizing heavy industry. Factories need massive amounts of heat—specifically steam—24/7. Solar and wind are great, but they aren’t always available, and standard batteries are too expensive to store the kind of gigawatts a chemical plant needs.

This is where the Rondo Heat Battery steps in.

Here is the setup: Covestro (a massive chemical giant) is installing a 100 MWh heat battery at their plant in northern Germany. But this isn’t a chemical battery. It’s essentially a giant toaster filled with thousands of tons of bricks.

How It Actually Works

I did some digging into the mechanics, and the beauty lies in its simplicity.

- The Input: The system takes excess renewable electricity (wind/solar) from the grid.

- The Storage: It runs that electricity through heating elements (like a toaster) to heat up specialized refractory bricks.

- The Output: These bricks hold heat at temperatures over 1,000°C. When the factory needs steam, air flows through the super-heated bricks, turns water into high-pressure steam, and feeds the factory pipes.

My thought: We’ve been using these types of bricks in steel blast furnaces for centuries. Taking that ancient reliability and pairing it with modern automated controls to store wind energy? That is pure engineering genius.

Why Germany? Why Now?

I found a fascinating statistic while researching this piece: In 2025, Germany recorded 573 hours of negative electricity prices.

That is a 25% increase from the previous year. “Negative prices” means there was so much wind and solar power on the grid that producers were practically paying people to use it.

Currently, most factories just burn natural gas to make steam because it’s reliable. But with this heat battery system, Covestro can:

- Buy electricity when it’s dirt cheap (or negative).

- Store it in the bricks as heat.

- Deploy it later when the sun isn’t shining or the wind isn’t blowing.

This allows them to decouple their energy usage from the grid’s volatility. It’s not just about being “green”; it’s a brutal economic advantage.

The Scale and Impact

This isn’t a small pilot project that will disappear in a year. When this system goes live in late 2026, it will be one of the largest industrial heat batteries in the world (alongside another Rondo unit in California).

Here is what the impact looks like at the Brunsbüttel facility:

- Capacity: 100 Megawatt-hours (MWh).

- Replacement: It will replace a significant portion of natural gas-fired boilers.

- Emission Cuts: It’s expected to save 13,000 tons of CO2 annually.

- Steam Load: It will cover about 10% of the site’s steam needs.

You might say, “Only 10%, Ugu?” But in heavy industry, shifting 10% of your baseload to a completely carbon-free source without disrupting operations is a massive milestone. It proves the concept works at scale.

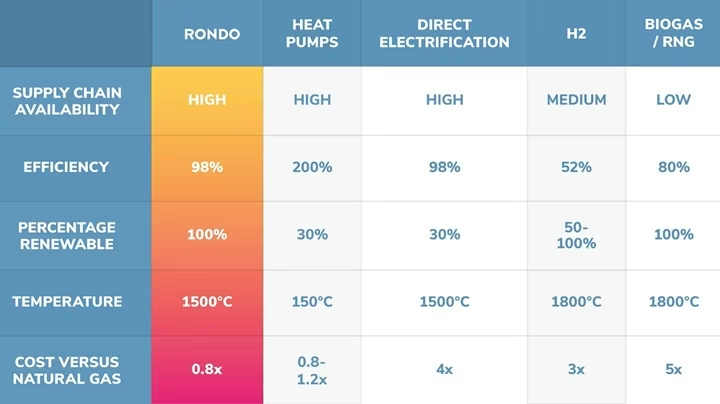

The Efficiency Stats Are Mind-Blowing

I am always skeptical about “loss” in energy conversion. Usually, when you convert electricity to heat and back, you lose a lot of juice.

However, Rondo claims a cycle efficiency of over 97%.

Because the heat is used directly (as heat/steam) rather than trying to turn it back into electricity, the losses are minimal. It solves the intermittency problem of renewables without the rare earth minerals required for chemical batteries.

Why This Matters for the Future

Think about this: 25% of the world’s total energy consumption goes into industrial heat. Not cars, not lights, but making things hot in factories to melt steel, process chemicals, or pasteurize food.

If we can replace the gas boilers doing that job with “electric bricks,” we solve a quarter of the climate puzzle.

Final Thoughts: The Return of the Brick

I love high-tech gadgets as much as the next person, but there is something incredibly satisfying about solving a modern crisis with ancient materials. We don’t always need a quantum leap; sometimes we just need to look at what we already have with fresh eyes.

For Covestro, this is a step away from fossil fuel dependency. For the rest of us, it’s a signal that the “Green Industrial Revolution” is finally getting its hands dirty with real solutions, not just buzzwords.

What do you think? Can “low-tech” solutions like heat bricks beat out advanced hydrogen or nuclear options for powering our industries? Let’s chat in the comments!